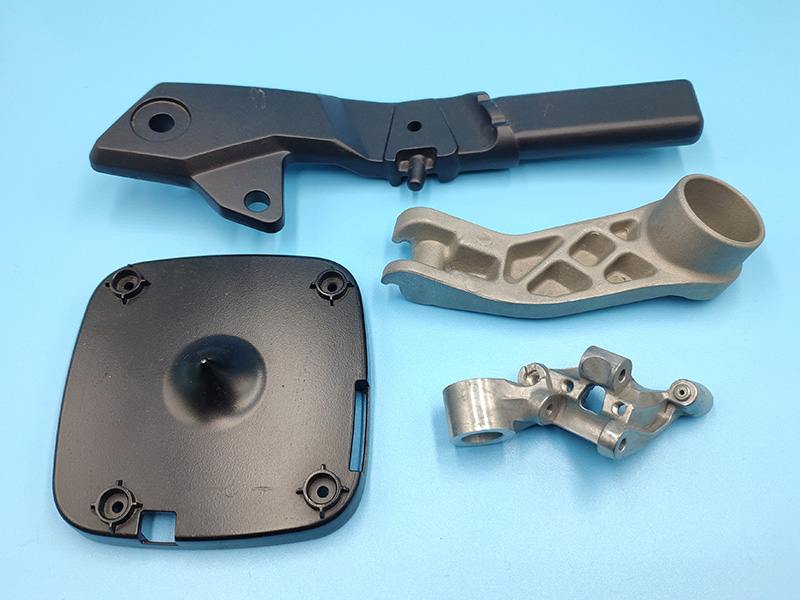

Some detailed about our Products:

1. Product Aluminum: Die Casting Anodized Machinery Parts

2. Material Aluminum: alloy ADC10, ADC12, A360, A380; zamark, etc

3. Manufactuering Process: Drawing and Sample...Mould Developing...Die Casting...Deburring...Drilling and Threading...CNC Machining...Polishing...Surface Treatment...Assembling...Quality Inspection..Packing...Shipping

4. Machine Capacity: Die casting machine 120 ton to 1200 ton

5. Surface Treatment: Polishing, Sandblasting, Painting, Powder Coating, Galvanizing, Chrome Coating, Anodizing

6. Application Example: Pneumatic components parts; Led light housing; Led heatsink; Auto, motocyle, bicycle parts; Furniture accessories; Power tool housing; Pump housing; Mechanical parts, etc

7. Drawing Available: IGS, STEP, SLD, X-T, XDF, DWG, SAT, STL, etc

More than 10 years of experience in aluminum die casting

Professional long working ages casting working people;

Experienced engineers;

Fast response of after sale

Advantages:

1. Lightweight--The weight of our aluminum is light.

2. Good mechanical properties

3. Corrosion resistant

4. High thermal and electrical conductivity

5. High strength—even at high temperatures

6. Retain high dimensional stability with thin walls and complex shapes